Plasma Cutting Aluminum Water Table

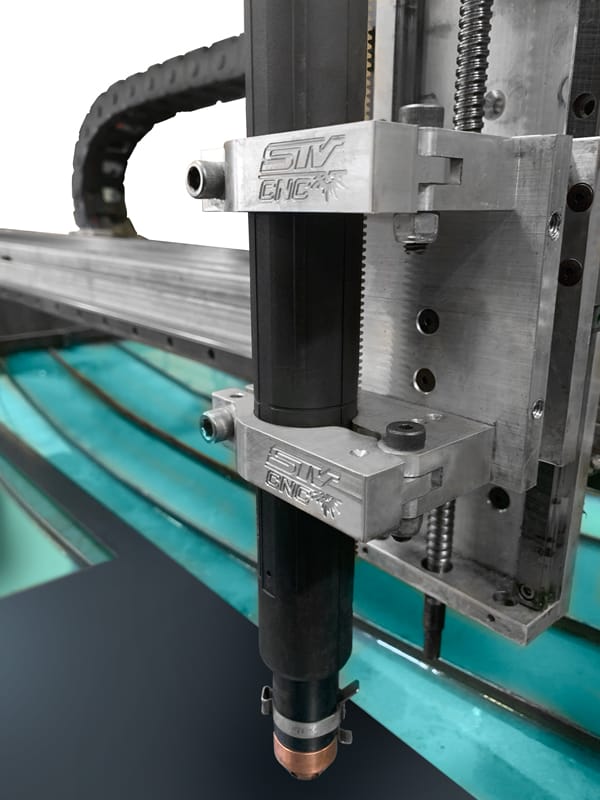

In simple words and terms plasma cutting aluminum is a procedure that makes use of a water table and also with the use of high velocity of inert gas usually delivered from an orifice.

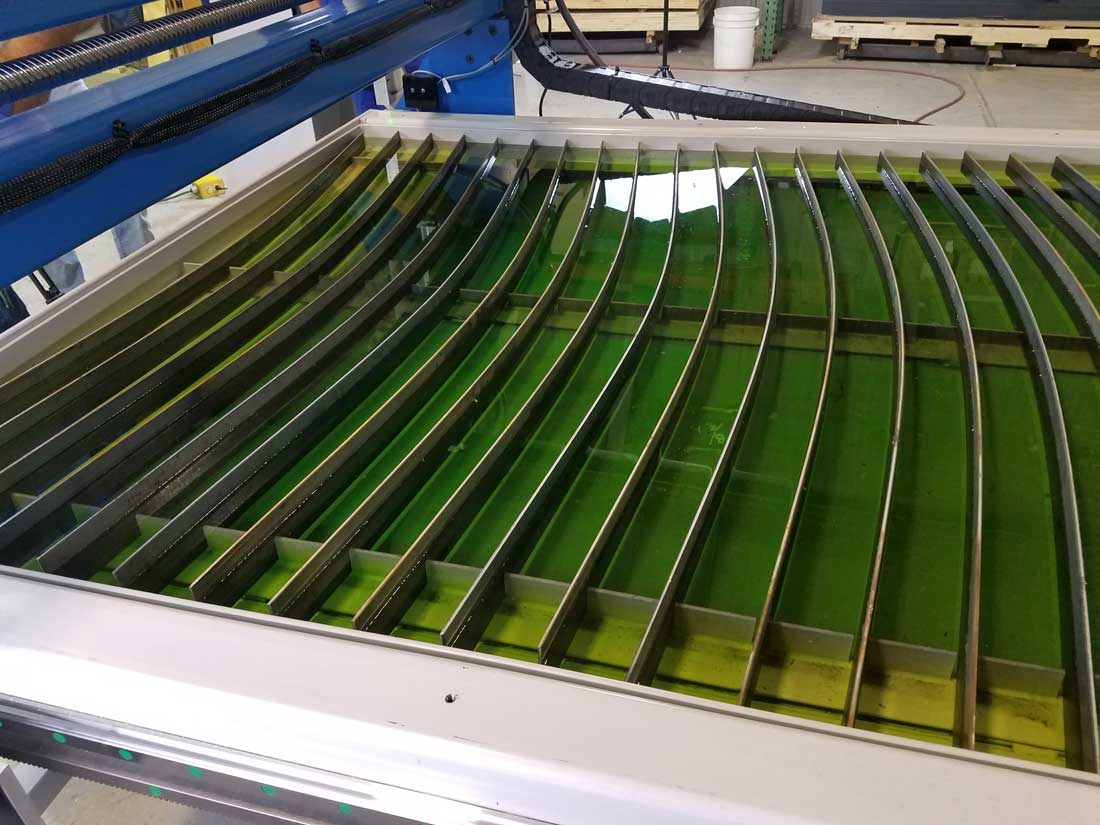

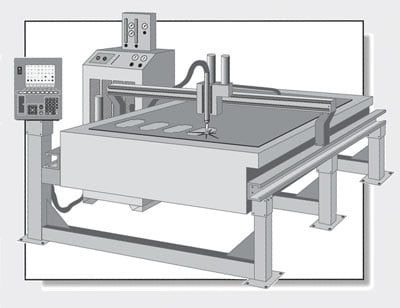

Plasma cutting aluminum water table. Built like a tank for both plasma and oxy fuel cutting the water cutting table option for park industries kano hd machines fits the bill. This is especially true of modern machines. Water table cutting table. When cutting aluminum with plasma over a water table small particles of aluminum and aluminum oxide form.

Reduces plate warpage. Those droplets especially the fine particles have a cumulative surface area that becomes very large over time and they can sit on the bottom of a water table for days weeks or months all the while generating hydrogen gas bubbles. The plasma which is the high velocity ionized gas conducts electricity right from the plasma s torch to the piece of work. Offering good fume control and a great shield flow for cutting stainless steel you can rely on this table for heavy duty cutting at a value based priced.

What is the best gas for plasma cutting aluminum. These particles cool as they hit the water and sink to the bottom of the table. Once at the bottom the aluminum oxide absorbs the oxygen leaving only hydrogen behind since water is composed of hydrogen and oxygen. A common problem seen plasma cutting aluminum is that you may not get a clean cut and have to spend a lot of time cleaning the edge down.

The standard water table with water level control is designed to be used for both plasma and oxy fuel cutting. Oxy fuel cutting on a water table. Or if you are using a hand held plasma cutter you can get a smaller water table for hand held plasma cutters. Plasma cutters are really useful and can make quick work of steel aluminum and stainless when they are correctly set up.