Preparing Tungsten For Aluminum Welding

Generally aluminum alloys are welded using alternating current ac.

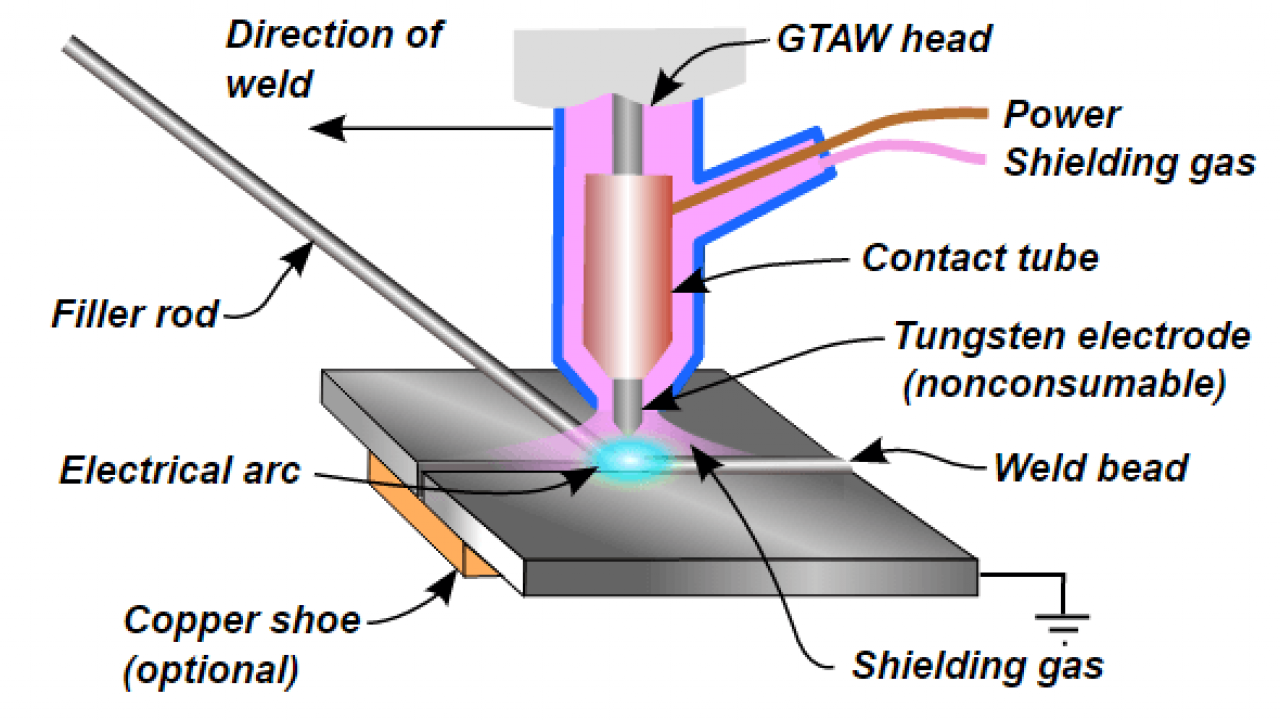

Preparing tungsten for aluminum welding. Tig stands for tungsten inert welding and in a more technical sense it s known as gas tungsten arc welding gtaw. Sharpen several at once. Though many processes can be used to join aluminum the most applicable process for lighter gauges and cosmetically appealing welds is gas tungsten arc welding. I am a welder in the navy and all we learn is carbon and stainless.

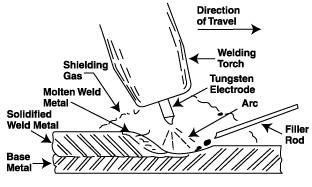

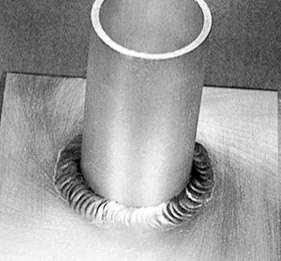

Use a round tip for welding aluminum using aluminum. The process utilizes a non consumable tungsten electrode that relays current to the welding arc. This produces a deeper weld and better scrubbing of the aluminum oxide. Pure tungsten green stripe for years was the best choice for ac welding but with the industry shift to invert based machines with advanced squarewave technology rare earth tungsten such as ceriated gray stripe and zirconiated brown stripe are an option.

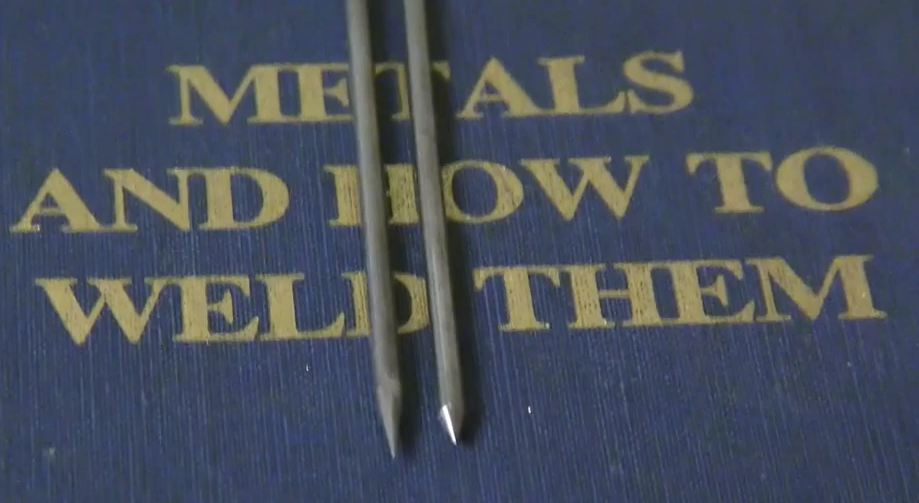

Choosing one of the six commonly available tungsten electrodes is a crucial first step in successful gas tungsten arc welding gtaw. There are various tungsten electrodes that you can use for the process but not all will prove efficient. I just would like to know how to properly prepare tungsten while welding aluminum i ve been using the red 2 tungsten and have had good results with both a balled end made by pumping the pedal a time or two on dcep and with a tapered end. A pointed tungsten allows the welding current to transfer in a focused arc and helps prevent thinner metals such as aluminum from becoming distorted.

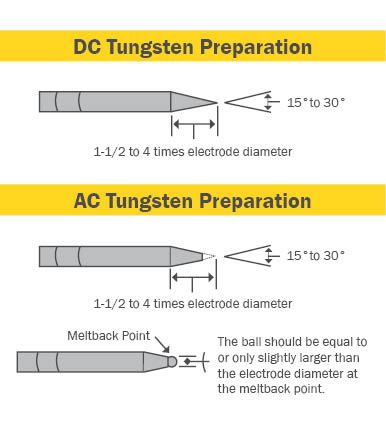

Tungsten electrode tip flat preparation the shape of the tungsten electrode tip is an important process variable in gas tungsten arc welding. Some other tips for preparing tungsten electrodes for welding. I ve been practicing aluminum here and there watching some videos online and lots of practice. The end preparations are balled pointed and truncated.

The electrode choices are pure tungsten 2 percent thoriated 2 percent ceriated 1 5 percent lanthanated zirconiated and rare earth. In this article we shall be discussing tungsten its applications tungsten electrodes for welding aluminum color coding and their types. To know the best tungsten for aluminum welding it s very important to understand what tungsten is all about. Aluminum s oxide coating higher thermal conductivity and lower melting point easily can lead to welding problems unless you know how to prepare for welding and set up the equipment.

When welding with lower currents on thinner materials those ranging from 005 to 040 in it is best to grind the tungsten to a point. I have been told there is a way to make the tip ball up a little but am not sure how to do this. If you have a handful of electrodes ready to go you can swap out electrodes when one gets contaminated. Tungsten prep for tig aluminum.

We will further go ahead to review the top 5 tungsten for aluminum welding.