Regenerative Thermal Oxidizer Service

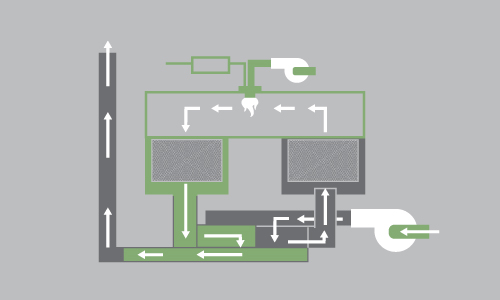

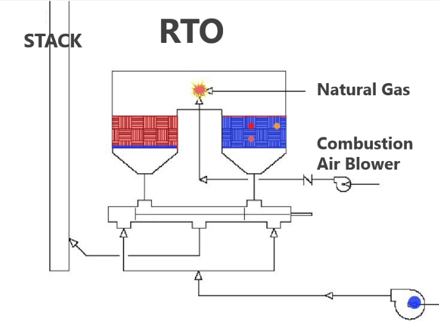

The regenerative thermal oxidizer rto ship shore s systems convert volatile organic compounds into carbon dioxide and water by using a system called a voc thermal oxidizer.

Regenerative thermal oxidizer service. We maintain and service our own systems as well as those made by our competitors. These regenerative heat exchangers can achieve considerably higher thermal efficiencies than a shell and tube or plate style. Regnerative thermal oxidizer the main argument for selecting the regenerative over the recuperative technology is the outstanding heat recovery efficiency which is achieved thanks to the extraordinary surface area of the heat storage media. This heat exchanger is comprised of ceramic material which can come in the form of saddles or honeycomb blocks.

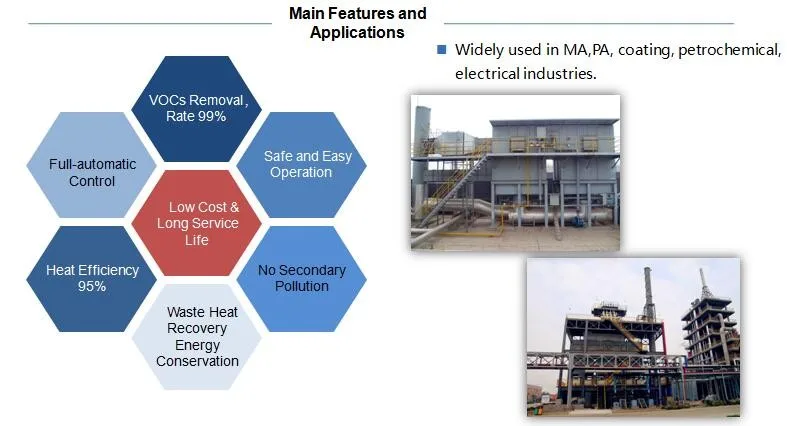

A regenerative thermal oxidizer rto is a piece of industrial equipment used for the treatment of exhaust air. As a manufacturer of air pollution control systems known as regenerative thermal oxidizers rtos alliance corporation takes pride in providing high quality products and services that meet our clients growing needs. It can be assumed that regenerative systems easily reach a thermal efficiency of 95 or even higher. This style of a air pollution process unit provides efficient air pollution control and is a industrial standard for facilities that require the destruction of hazardous air pollutants haps volatile organic compounds vocs and other odorous emissions that are discharged during industrial or manufacturing processes.

However alliance corporation does offer field repairs of our competitor s equipment. A regenerative thermal oxidizer utilizes a unique regenerative style heat exchanger. We don t have much call for repair of our own products. The system is a type of thermal oxidizer that uses a bed of ceramic material to absorb heat from the exhaust gas.

This model of thermal oxidizer uses a high efficiency heat exchanger to heat the incoming process air from 200 f to 700 f reducing the required temperature rise over the burner to reduce natural gas usage and lower operating costs. A regenerative thermal oxidizer rto is a specific type of thermal oxidizer that repurposes the thermal energy generated during the air pollution control process. Regenerative thermal oxidizer systems the regernative thermal oxidizerpurifies the air flows from industrial or manufacturing processes by destroying hazardous air pollutants haps volatile organic compounds vocs and discharged odorous emissions. The recuperative thermal oxidizer is a popular design due to lower energy costs.

It then uses this captured heat to preheat the incoming process gas stream and destroy air pollutants emitted from process exhaust streams at temperatures ranging from 815 c 1 500 f to 980 c 1 800 f.