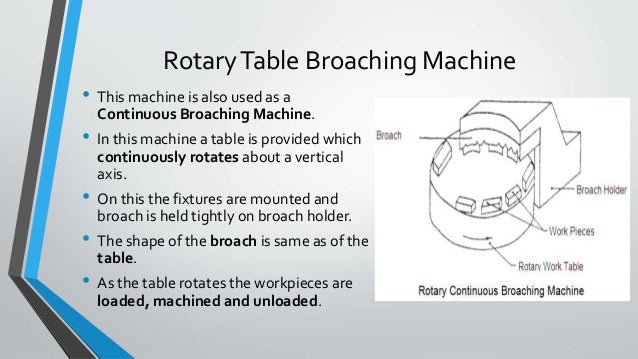

Rotary Continuous Broaching Machine

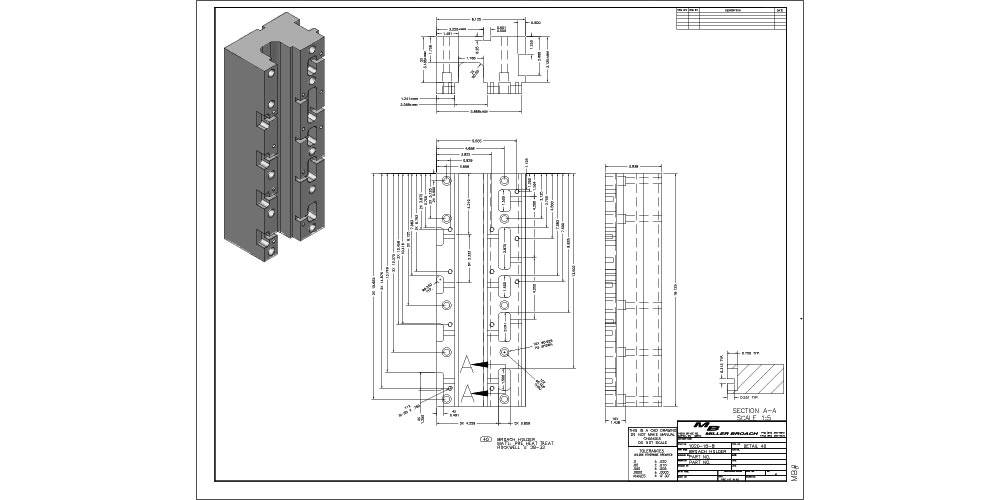

Horizontal broaching machines are designed for pull broaching surface broaching continuous broaching and rotary broaching.

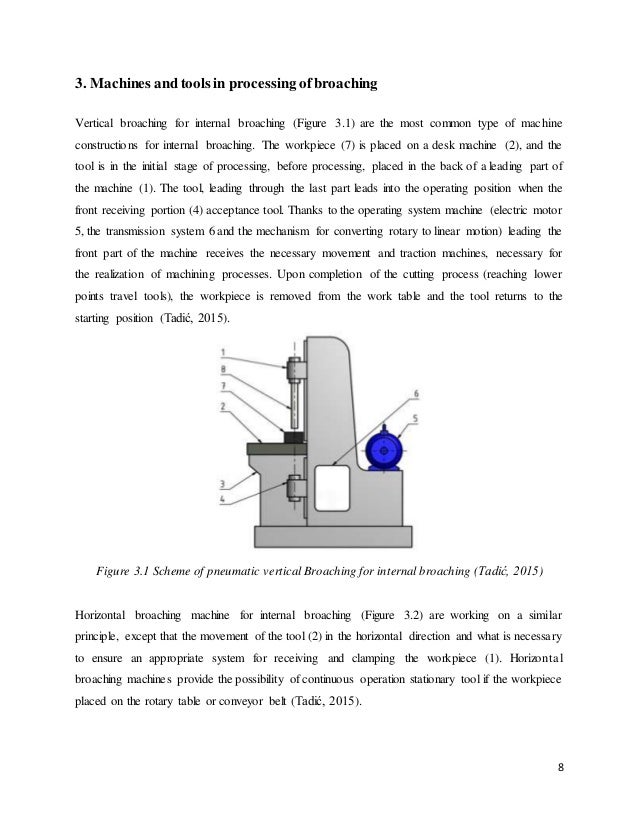

Rotary continuous broaching machine. Since 1951 slater tools inc. Rotary broaching is a precision method for producing internal polygon forms at an extremely fast. On some surface broaching machines the ram travels horizontally on others ram travels vertically. Polygon solutions innovative and award winning rotary broaching tools are used by a variety of precision machining companies.

Slater tools designs manufactures and delivers the finest most competitive turning industry tools such as rotary broaching tool holders broaches retractable live centers and screw machine tooling. This orientation creates a shearing effect around the edges of the form being cut essentially only a section of the form is. When two rams are used the machines is called a duplex broach. Has proudly maintained an excellent reputation for quality and service.

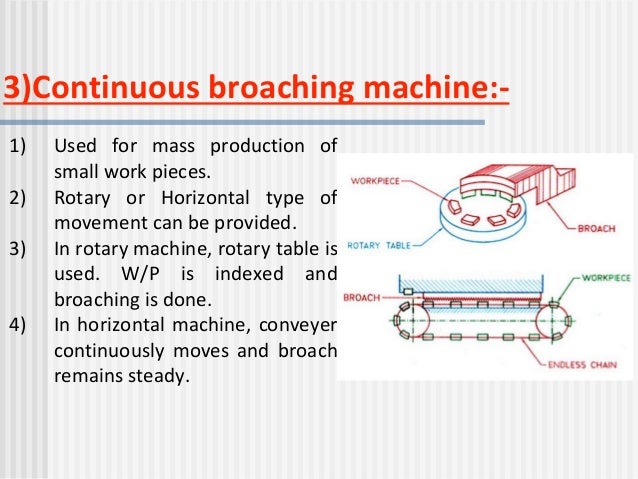

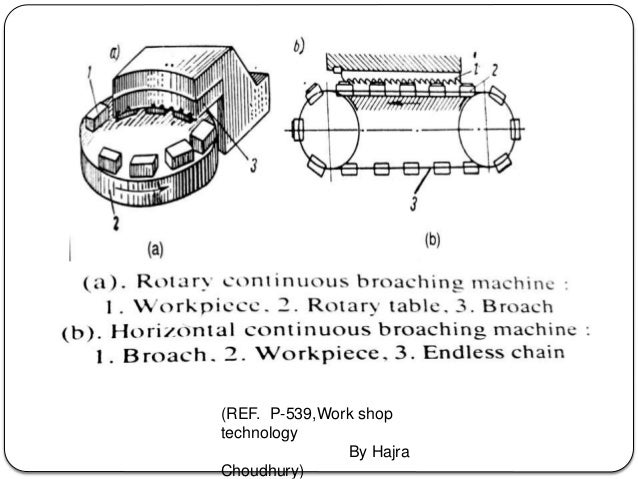

Surface style machines hold the broach stationary while the workpieces are clamped into fixtures that are mounted on a conveyor. This works exceptionally well on horizontal or vertical spindle machines such as lathes mills etc. For mass production of small parts the highly productive continuous broaching method is used on rotary or horizontal continuous broaching machines. The process works because the head of the broaching holder is offset from the centerline of the shank on a 1 degree angle.

Rotary broaching can achieve this in one pass by cutting the full form one corner at a time often eliminating the need for a secondary operation.