Rotary Table Bearing Arrangement

For the design of the bearing arrangement this means.

Rotary table bearing arrangement. The main advantage of this bearing is it takes loads when table rotated clockwise and anticlockwise direction as shown in figure 2 bearing arrangement for table support the top surface of the. Table 1 performance data of rotary axis. A guide to bearing selection rotary table bearings have due to their geometry and design quite specific characteristics. The rotary table from above the rotary table bearing arrangement must provide the entire supporting force.

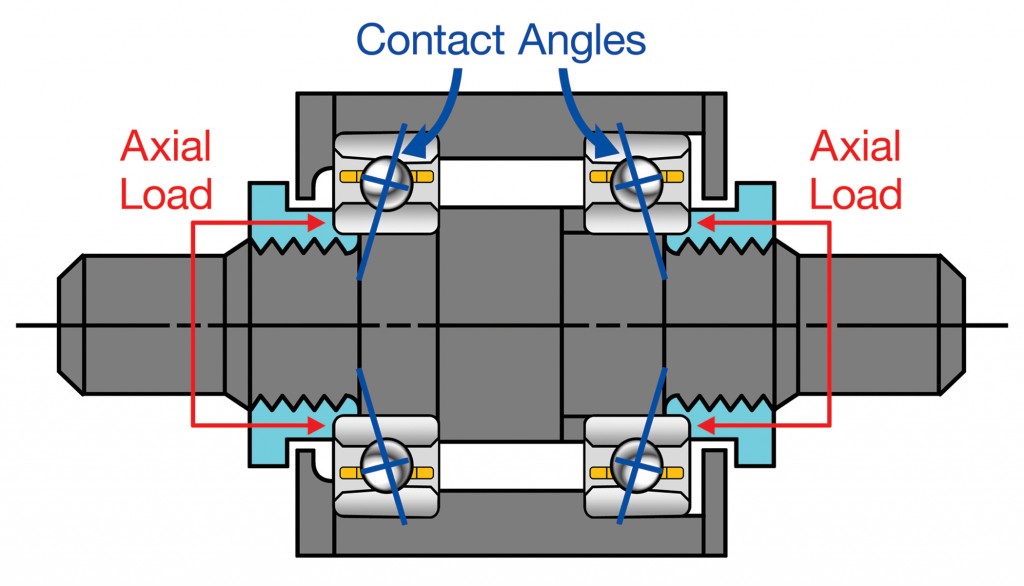

Circumferential speeds up to 20 m s rotational speeds up to 300 rpm. It adopts sliding mode to rotate the transmission. The new series rotary tables are with double acting double piston arrangement which generates higher clamping thrust ensuring positive and faster clamping declamping of rotary tables. This type of bearing arrangement ensures very high static rigidty of the subassembly which is important in achieving precise and dimensionally accurate machining even when applying large machining forces.

The race rings in the franke wire race bearings can be arranged individually and also combined to form multi row bearings. Specially processed high friction disc enables higher clamping torque. If an additional magnet bearing arrangement is integrated in the rotary table such that the rotating magnets in the rotary. The measuring system integrated in the bearing also benefits from the extremely precise radial runout of the precision rotary axis bearing yrtcma.

At the current level of technological development rotary tables are predominantly equipped with ready to fit rolling bearing arrangements. The relevant bearing arrangement. They can support radial loads axial loads from both sides and tilting moments without clearance and are particularly suitable for bearing arrangements with high requirements for running accuracy such as rotary tables face. Yrt precision rotary table bearing is a kind of bearing fixed by a bidirectional thrust bearing and a centripetalguided bearing.

Arranged as angular contact ball bearings they become highly dynamic rotational systems for high end applications.