Screen Printing Ink Types Pdf

Move the squeegee to the back side of the ink ready to pull it back across the artwork.

Screen printing ink types pdf. They come in different varieties. This is a process wherein dirt and oils that have been transferred to the screen are washed away so. Plastisol is your standard screen printing ink. Screen printing inks need to have solvents with moderately high boiling points.

What type of screen printing ink do you need for that project. Discharge inks which recently gained increasing popularity may come in waterbased and plastisol varieties. There are many different types or rather methods of printing such as typographic flexographic lithographic gravure screen and nip or non impact printing such as ink jet printing. With the screen still elevated push the ink lightly over the screen away from your body to coat the artwork.

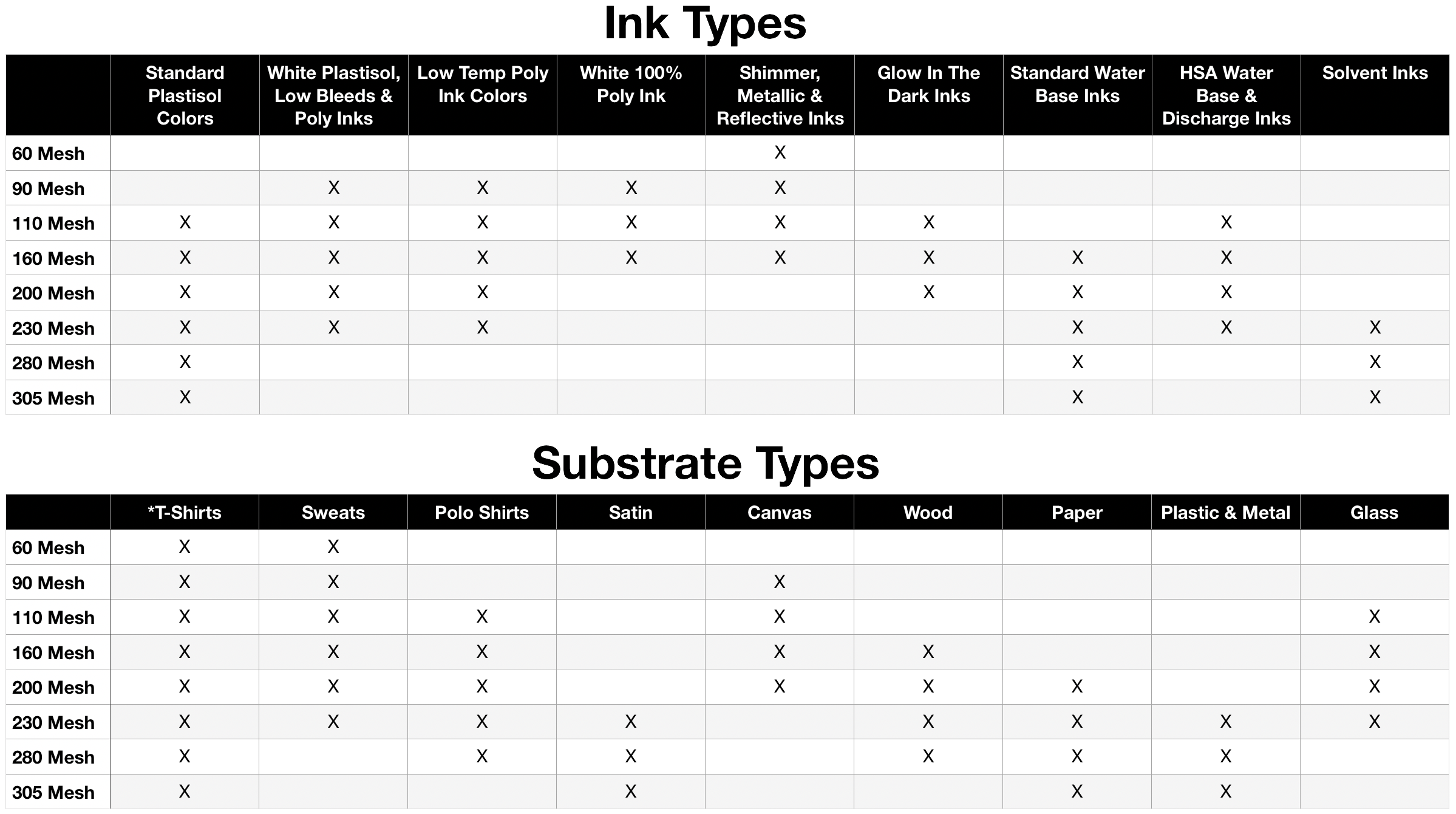

Screen printing ink types. Some commonly used solvents are listed in table 3. Please note on tri blend material you will see a great deal of the heathering through the print. Screen type or types will work for the job ahead.

Icon team member 4 2 2014. Because water based and plastisol inks are the two most widely used for garment printing our primary focus will be on those. Learn more on this episode of screen printing real talk. Ink is a colloidal system that is typically comprised of colorant vehicle solvent and additives.

See figure one for the sales of different inks in the u s. Check out our conversation about. Water based inks are the best option for eco friendly screen printing but don t work as well as plastisol on certain fabrics or if you need an ultra bright print. Although screen printers may utilize a multitude of different ink over the course of their career most are likely to use just two or three for printing on garments.

The two main types of screen printing ink are water based and plastisol. Inks as the solvent used must be viscous and hydrophobic. The different types of screen printing ink include water based plastisol and discharge inks. Some solvents used in screenprinting inks 2 4 additives many different types of additives are used to alter the final properties of the paint.

Sample photos with discharge inks. The first step in screen preparation is the degreasing process. Lower the screen onto the paper the screens are weighted so the raising lowering is super easy.