Stainless Steel Electrodes Water Electrolysis

Dioxide materials offers one stop shopping experience for electrochemical equipment for co2 and water electrolysis and.

Stainless steel electrodes water electrolysis. Some additional materials required. Therefore when electricity is applied to the electrode the available current can be minimized 6 8. Electrode materials must be stable at high anodic. Anode electrode for a water electrolyzer hand painted on stainless steel fiber paper.

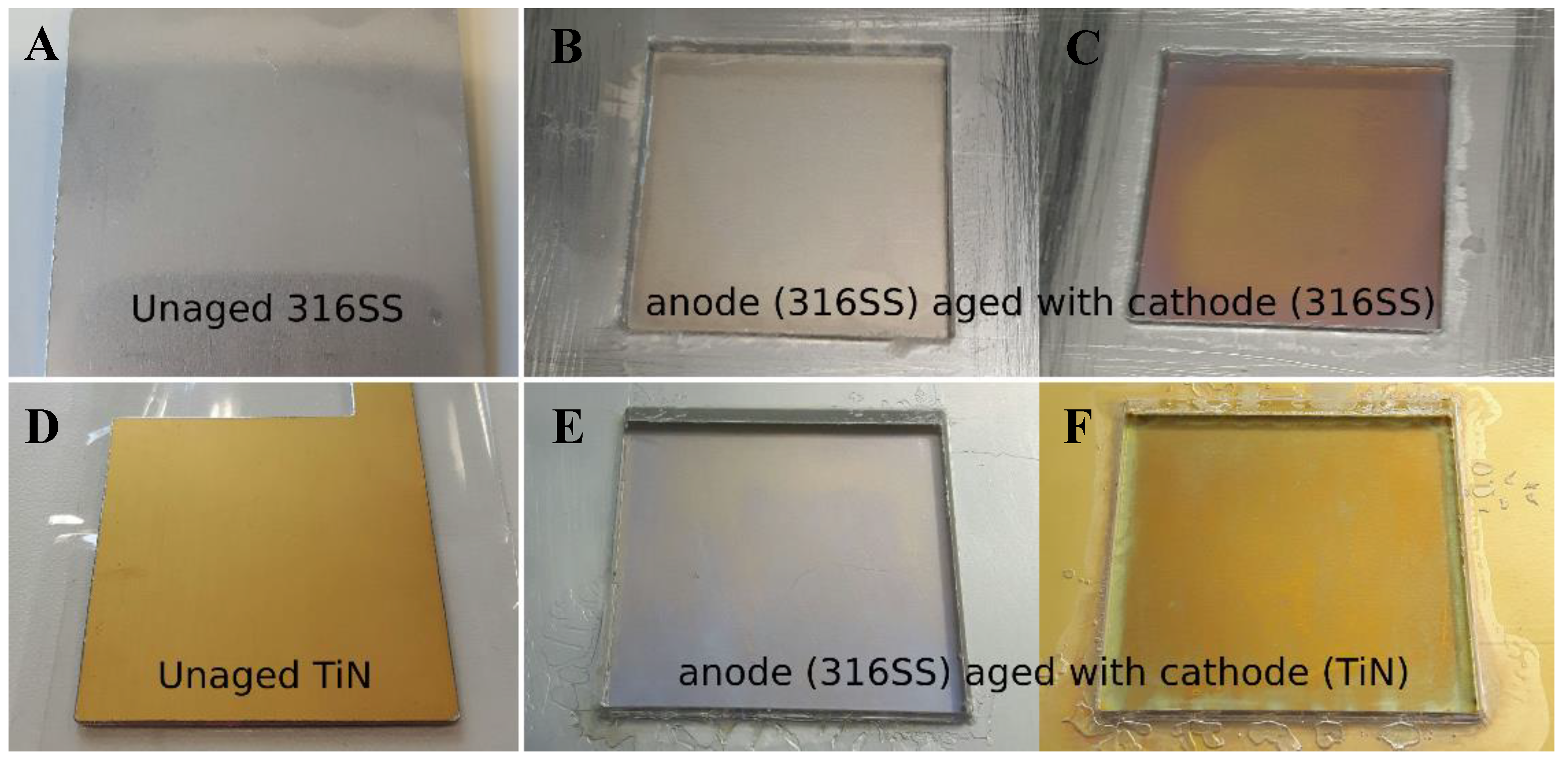

Stainless steel is indeed consumed when used in the electrolysis process although slowly. The electrodes and thus the chromium is consumed and you end up with poisonous chromates in your electrolyte. Operations using such ss bearing materials proceed under substantial overpotentials above the thermodynamic requirement due to the sluggish kinetics of the anodic oxygen evolution reaction oer. In modified ni electrodes cr 6 was detected within norm in the electrolyte.

Its a very old pool with a concrete bottom and stainless steel walls. Electrodes used in this research is a stainless steel 316 and naoh solution used as the electrolyte. Cr 6 was detected out of norm in electrolyte using stainless steel electrodes. Cr 6 is very dangerous metal ion generates different types of cancer in people.

Use this pair of stainless steel insulated electrodes to demonstrate electrolysis of water into hydrogen and oxygen. Will not corrode quickly like copper. Someone suggested that it is happening because of the salt. I ve come across a pool that has issues with stainless steel wall panels rusting.

You need something that will resist corrosion while remaining electrically conductive. Each anode catalyst is custom made and hand painted on stainless steel fiber paper. The reason this is difficult is becaus. You can use pretty much any metal for the cathode the electrode that evolves hydrogen but the anode is more difficult.

Efficiency of electrolysis equipment can be improved by considering the effective surface of electrodes. Stainless steel ss has been widely incorporated into electrodes or used as a conductive scaffold in industrial water electrolysis. One of the challenges to widespread use of water electrolysis is to reduce maintenance time. I wouldn t suggest copper including copper alloys or aluminum for either electrode because they corrode rapidly when used for electrolysis.

The main problem with using it is the hazardous waste it produces. At the joints between the walls there is almost always an accumulation of rust.