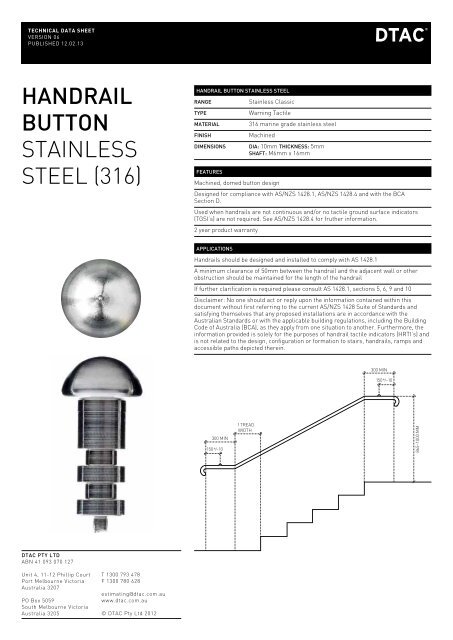

Stainless Steel Grade 316 Australian Standard

Plasma cutting is normal.

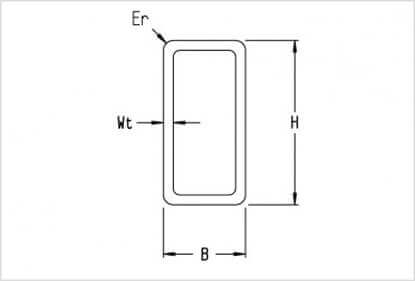

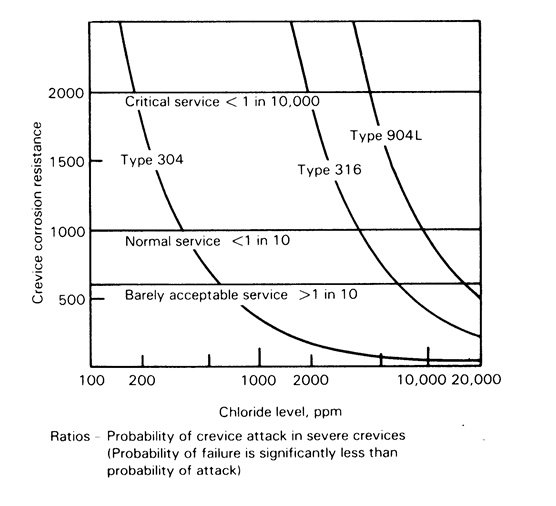

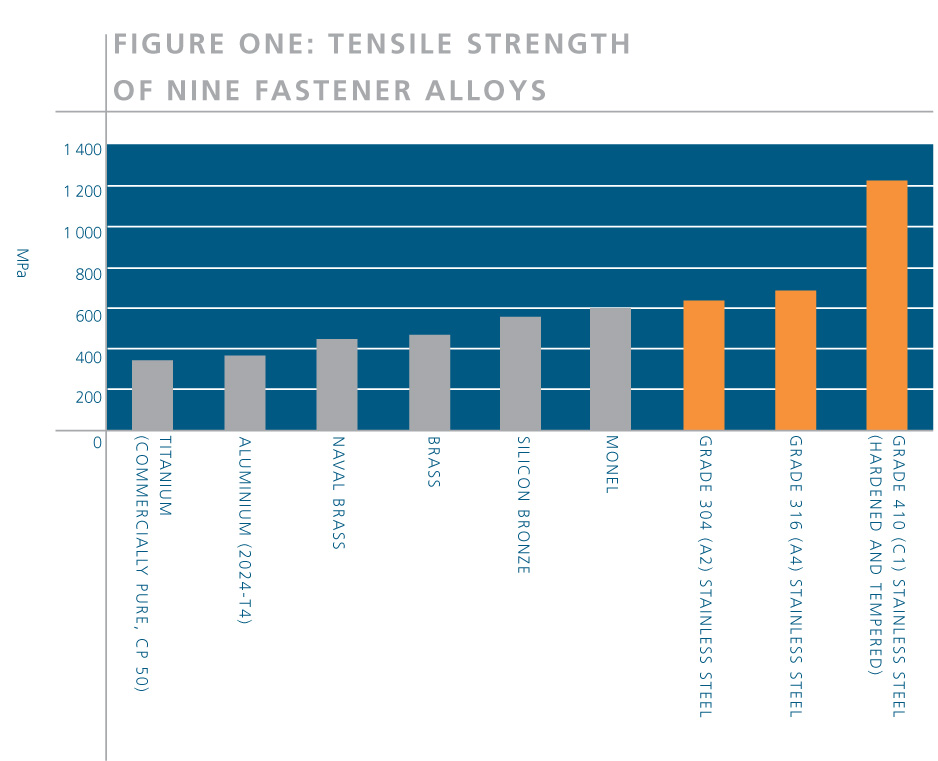

Stainless steel grade 316 australian standard. This is particularly apparent for. Stainless steel pipes and tubes for pressure applications. Both had a molybdenum content in the range of 2 25 3 0. The molybdenum gives 316 better overall corrosion resistant properties than grade 304 particularly higher resistance to pitting and crevice corrosion in chloride environments.

It withstands ordinary rusting in architecture is resistant to most food processing environments and resists organic chemicals dye stuffs and a wide variety of. It has excellent forming and welding. Aisi 316 grade stainless steel is suitable for cold working such as cold heading cold drawn and cold riveting but it is more difficult than carbon steel. Stainless steel grade 316 1 4401 stainless steel types 1 4401 and 1 4404 are also known as grades 316 and 3164l respectively.

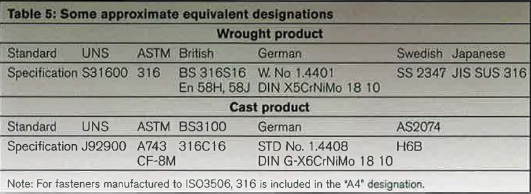

A low carbon with 0 03 max 316s12 and a standard carbon with 0 07 max 316s16. Sae 316l grade stainless steel sometimes referred to as a4 stainless steel or marine grade stainless steel is the second most common austenitic stainless steel after 304 a2 stainless steel. The deep drawing capability of grade 316 is outstanding because of its high austenite stability. The specification of bar to bs970 and coil plate to bs1449 before 1983 covered two type 316 grades.

316 is one of the easier austenitic stainless steels to forge at temperatures above. Welded stainless steel tubes for plumbing applications. 316 stainless steel contains an addition of molybdenum that gives it improved corrosion resistance. Comparison of composition ranges of 316 type stainless steels introduction.

Grade s30400 stainless steel s30400 is the most specified grade it accounts for more than 50 of stainless steel produced in the world and services a wide range of applications. Aisi 316 stainless steel has higher strength and higher work hardening rate than carbon steel and low alloy steel so it is more difficult to process. Plumbing and drainage products part 053. Welded stainless steel tubes for plumbing applications.

Its primary alloying constituents after iron are chromium between 16 18 nickel 10 12 and molybdenum 2 3 with small 1 quantities of silicon phosphorus sulfur also present.

%20vs%20SS%20316(18-10%20Stainless%20steel).jpg)