Stainless Steel Mig Welding Gas Mixture

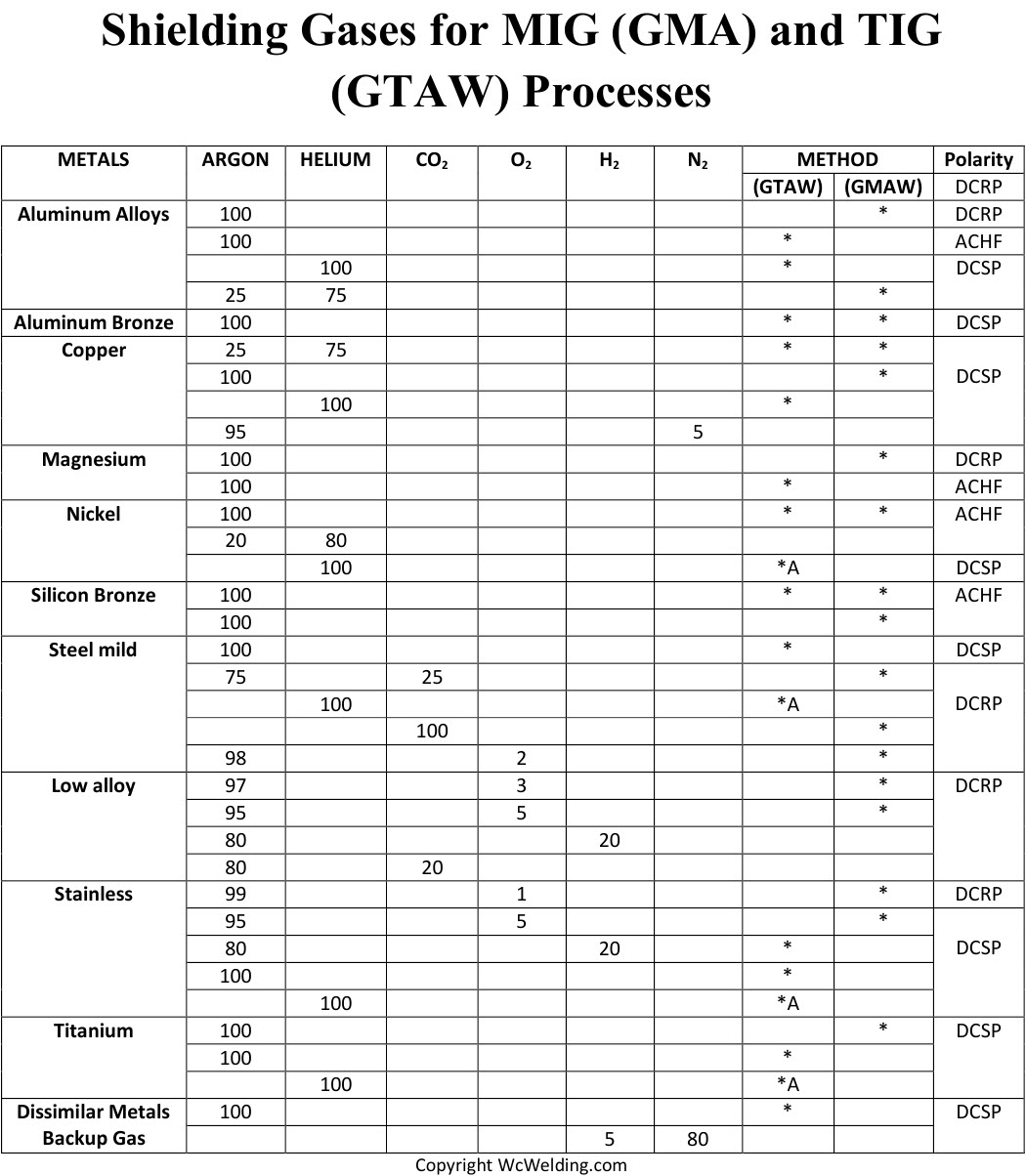

Dcep direct current electrode positive is used for most stainless steel welding.

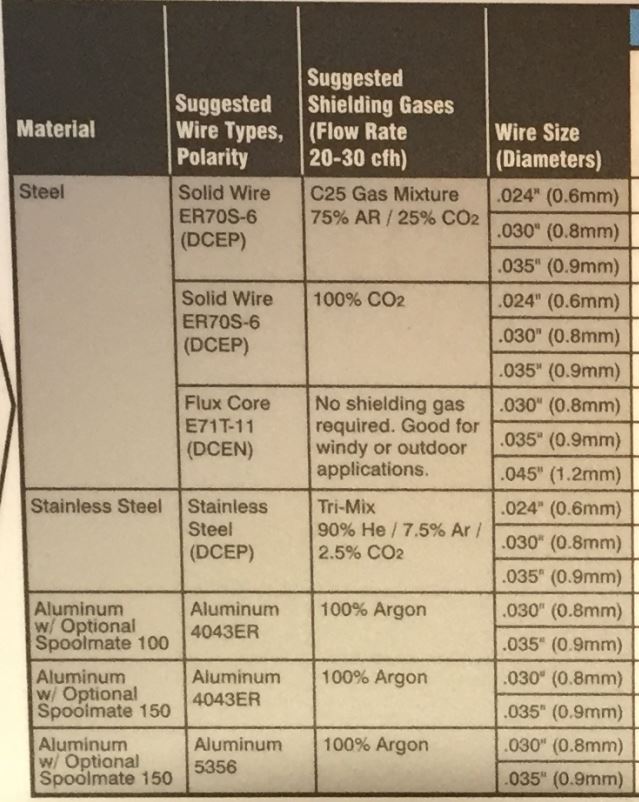

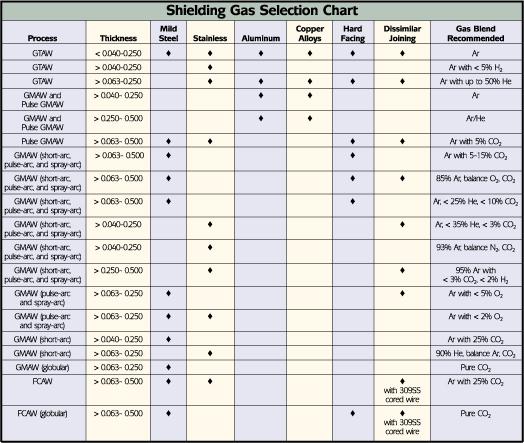

Stainless steel mig welding gas mixture. And for that matter the reason argon gas. A 1or 2 argon oxygen mixture is recommended for most stainless steel spray arc welding. In some cases there is tri mix shielding gas containing 90 helium 7 5 argon and 2 5 carbon dioxide. Alternative gases that you can use are 98 argon and 2 co2 or 98 argon and 2 oxygen mix.

Welding of stainless steel is typically done with mixture of argon and carbon dioxide gasses that can be as low as 2 carbon dioxide to as high as 25 carbon dioxide. Welding of stainless steel is typically done with c2 or 2 carbon dioxide and 98 argon. 25 carbon with 75 argon gas is the most commonly used shielding gas for home and hobby mig welders. In some cases there is tri mix shielding gas containing 90 helium 7 5 argon and 2 5 carbon dioxide.

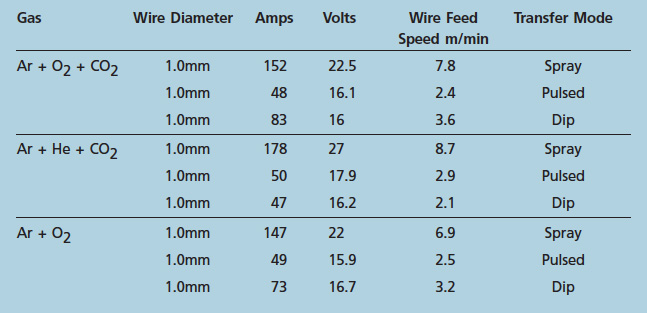

100 co2 and a 25 75 carbon argon mix. Two types of gas combinations are preferred in mig welding for mild steel. When it comes to the gases used in normal welding for carbon steel many welders used the c25 mixture that consists of co2 25 and argon gas 75 because co2 cannot be used separately in some cases as it creates a deeper penetration along with lots of smoke and even may cause a rough looking weld. Mode of metal transfer.

The degree of spatter is dependent upon the composition and flow rate of the shielding gas wire feed speed and the characteristics of the welding power supply. Mig welding gas for stainless steel welding. Mixtures of 80 percent argon and 20 percent co2 as well as 90 percent argon and 10 percent co2 are also common mig welding gases n d. For years the industry standard gas blend for short circuit welding of stainless steel was a helium based 85 to 90 percent trimix with small additions of argon 5 to 10 percent and co 2 2 to 5 percent.

Tri mix gas 90 helium 7 5 argon and 2 5 carbon dioxide.