Spray Aeration Water Treatment

Spray aeration removes low levels of volatile contaminants especially radon.

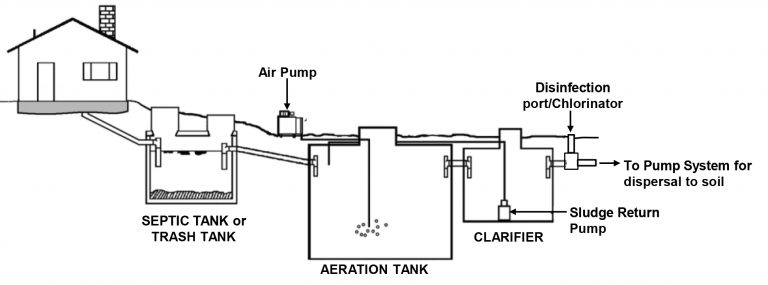

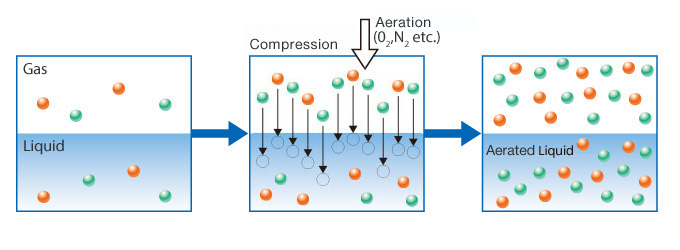

Spray aeration water treatment. Spray aerators have one or more spray nozzles connected to a pipe manifold. Aeration accounts for about 50 of a wastewater treatment plant s energy bill and can consume significant maintenance resources to maintain performance. Aeration is used in liquids soils and foods to improve quality and reduce contamination. Radon and other volatile contaminants are released and vented to the outside.

Reducing these operational costs while meeting today s stringent permit limits is imperative for municipalities and industries today. Water moves through the pipe under pressure and leaves each nozzle in a fine spray and falls through the surrounding air creating a fountain affect. It is an integral part of most biological wastewater treatment systems. But it has certain limitation to using the spray aerators system 1.

Aeration in water treatment is a must have process for the water bodies suffering from anaerobic conditions that are often caused by human activities such as excessive fishing done in the lake or sewage discharges. Aeration is the process of increasing the oxygen saturation of the water as a result which produces active sludge that can be used as fertilizers. The process of maintaining the oxygen saturation levels of water in natural as well as artificial environment is termed as aeration. Spray aeration is successful in oxidizing iron and manganese and increases the dissolved oxygen in the water.

Spray aeration is the process of pumping water from the floor of the tank to the ceiling and spraying it down through a set of spray nozzles. In industrial use the most common method of aeration is water fall aeration through the use of spray nozzles. Aeration aeration is an important step in the process of water and wastewater treatment. As each droplet flies out of spray nozzle thms evaporate out of the droplet and into the air.

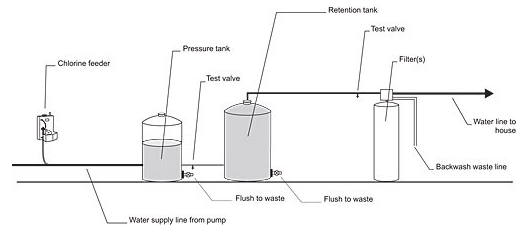

This process of adding air into wastewater allows aerobic biodegradation of the pollutant components. Treated water collects in a vented tank below the spray heads. There is also the air diffusion method of aeration in which air is diffused into a receiving vessel containing counter current flowing water. Spray aerators are usually efficient with respect to gas transfer such as carbon dioxide removal or oxygen addition normally spray aeration is successful in oxidizing iron and manganese and is successful in increasing the dissolved oxygen of the water.

Spray aeration in the back end clearwell strip thm from the clearwell with spray aeration. In many systems this is the best option particularly if there is no guarantee the water will ever enter a distribution tank where it can be stripped of thm since often the water goes from the clearwell directly to a consumer s faucet.